The SCORPION® 2 Digital Humidity Sensor is designed to measure the moisture content, of the thermal environment, in both heating and cooling processes. It is applicable to proofers, ovens, dryers and cooling tunnels.

The SCORPION® 2 Digital Humidity Sensor is designed to measure the moisture content, of the thermal environment, in both heating and cooling processes. It is applicable to proofers, ovens, dryers and cooling tunnels.

Mechanically the Digital Humidity Sensor is comprised of an Air Temperature sensor, two inputs for Product CoreTemperature Measurement and a proprietary humidity sampling system to measure Dew Point Temperature, Absolute Humidity and Relative Humidity. The sampling system contains patented Anti-Saturation Technology™ allowing measurements in very high dew point environments such as steam injection.

The Digital Humidity Sensor is engineered to be compatible with direct gas fired (DGF) ovens. Unlike oxygen sensor technology, which can be off by as much as 25% due to combustion gases in DGF ovens, the accuracy of the digital humidity sensor remains the same regardless of the oven platform.

The Humidity Sensor travels through the process with the product, yielding a precise profile of moisture experienced by the product.

Why is Humidity Profiling important?

Humidity in a thermal process interacts with the product. The moisture in the environment often comes from the product itself and represents a delicate balance affecting finished product quality in many ways.

Humidity in a thermal process interacts with the product. The moisture in the environment often comes from the product itself and represents a delicate balance affecting finished product quality in many ways.

For example:

- The amount of moisture left in a product can determine its shelf life.

- Reduced evaporation can keep the surface of a product moist, allowing it to stretch, preventing cracks.

- Low humidity in a cracker oven can cause blisters leading to undesirable dark spots and excessive breakage.

- The lack of humidity in a cookie oven can cause case hardening preventing internal moisture from escaping leading to checking (the spontaneous cracking of the cookie after baking).

- High humidity in bread ovens produces the desirable glossy crust seen on many bread products. For this reason steam injection is often used.

- High humidity will assist with the killing of pathogens, like salmonella, potentially found in surface toppings.

Product throughput lb/hr (kg/hr) can also be affected by when and how much moisture builds in a process. Moisture laden environments reduce baking efficiency, thereby reducing product throughput.

Analyzing the Results

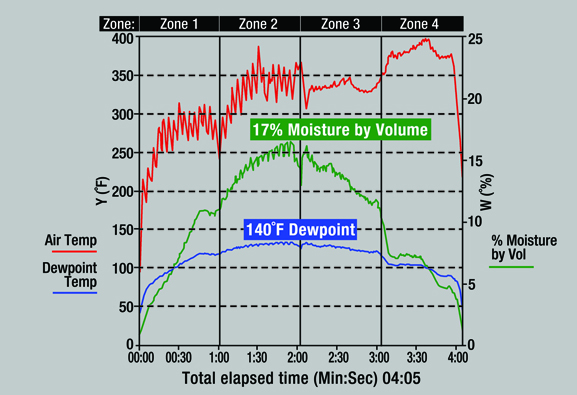

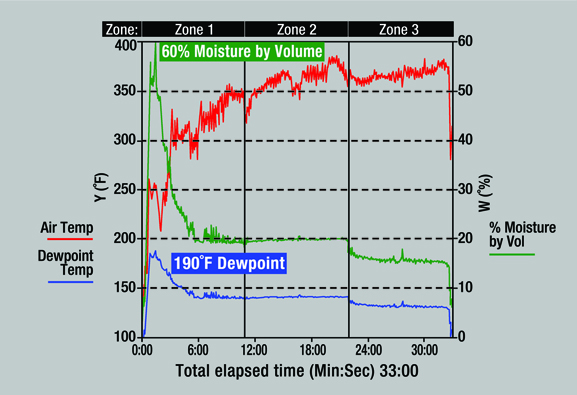

In high temperature applications above 212°F (100°C), absolute humidity is displayed. The user can choose between % Moisture by Volume or Humidity Mass Ratio (lb water/lb dry air or kg water/kg dry air).

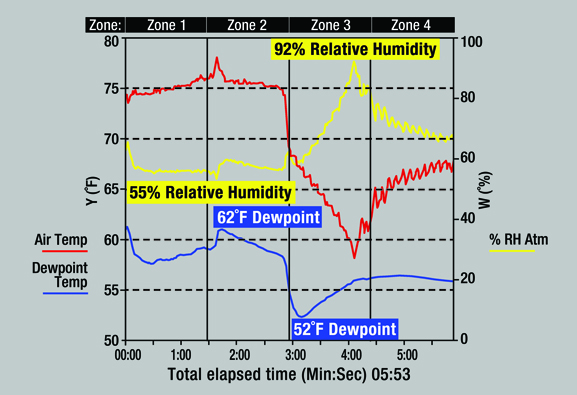

In low temperature applications below 212°F (100°C), % Relative Humidity is displayed.

In both high and low temperature applications, the dew point temperature and dry bulb air temperature is displayed.

Humidity in ovens is generally controlled by extraction fans and dampers. Here the sensor is used to display the shape of the humidity profile as well as the peak moisture value obtained and where. In proofers it is used to document the temperature and relative humidity of the proof cycle. In cooling tunnels it is used to monitor dew point temperature, preventing condensation on the product surface which causes blooming.

Bread Oven with Steam Injection

Bread Oven with Steam Injection

- Steam injection causes a high %Mv and Dew Point in the first zone.

- A glossy crust will be produced.

- High moisture will assist with killing pathogens found in surface toppings.

- A perfect bell shaped moisture curve is displayed.

- Case hardening leading to checking will be prevented.

- Dew Point is closely monitored to prevent surface condensation.

- Aggressive cooling is displayed in zones 3 and 4.

The length of time the Humidity sensor can be in a heated process is dependent on process temperature and airflow. The Digital Humidity Sensor Dwell Time must always be the determining factor when using this sensor.

Technical Recommendation

by Bill Hagan

Bill Hagan, technical sales manager for AB Mauri North America, has been profiling ovens, proofers and coolers using the SCORPION®2 Digital Humidity Sensor. Mr. Hagan said that being able to measure humidity throughout the entire baking process, particularly in the oven, allows him to give bakers information that was previously not possible. He further incorporated AB Mauri’s knowledge base to assist and utilize the sensor for use in bread and roll production.

Bill Hagan, technical sales manager for AB Mauri North America, has been profiling ovens, proofers and coolers using the SCORPION®2 Digital Humidity Sensor. Mr. Hagan said that being able to measure humidity throughout the entire baking process, particularly in the oven, allows him to give bakers information that was previously not possible. He further incorporated AB Mauri’s knowledge base to assist and utilize the sensor for use in bread and roll production.

“Data from oven profiling provides absolute humidity measurements verifying steam applications and proper oven exhaust settings. Analysis of proofer data indicates relative humidity throughout the process, allowing the proper settings for optimal proof which yields the desired dough piece texture entering the oven,” Hagan said. “Profiling air-conditioned bread and bun coolers displays relative humidity through the cooler. This data can indicate too much evaporation during the cooling process, thereby drying out finished product prior to being packaged.”

Mr. Hagan recommends the SCORPION®2 Digital Humidity Sensor as an extremely versatile instrument used to document, troubleshoot and improve quality of the complete baking process.

Case Study

Humidity vs. Efficiency within Ovens

Problem: A pretzel company has two similar production lines baking pretzel products. One oven bakes more efficiently than the other, consistently producing more pounds per hour… Click the case study link above to see how Humidity Profiling helped solve this problem.

Printable Version

Dr. Lin, founder of BakerPedia.com, discusses the critical nature of understanding and controlling steam in your Bread and Bun processes. Dr. Lin points out how doing an oven profile using the Reading Thermal Digital Humidity Sensor can help you obtain the desired product quality and throughput and identify factors keeping you from it.