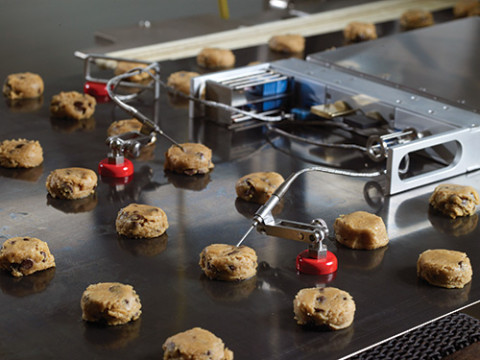

Baking your products to perfection requires utilizing thermal profiling technology to optimize the baking process. Reading Thermal offers the state-of-the-art SCORPION® 2 Profiling System that can help you make adjustments that will achieve superior products.

Reading Thermal, headquartered in Sinking Spring, Pennsylvania, has focused on researching the commercial baking process for more than 25 years. We manufacture and support the state-of-the-art SCORPION® 2 Profiling System and Data Logger that has become a standard in the baking industry.

Measuring Oven Temperature

Oven temperature impacts oven-spring, drying/dehydration, and color formation during baking. Insufficient or excessive heat can also lead to unwelcome changes in texture and taste. The Scorpion® 2 Temperature Sensor Array measures the temperature at product level, in fixed positions across the conveyor, and delivers a precise picture of temperatures from side-to-side and end-to-end.

Other Important Sensor Measurements

Connecting smart sensors and sensor arrays to the SCORPION® 2 Profiling System and passing them through the oven with the product, enables the measurement system to capture the four main baking parameters:

1) Heat flux (energy transfer): Certain product characteristics are defined by the amount and type of heat applied during the baking process. The differences explain why one oven bakes differently than another. And analyzing and controlling these differences is critical to understanding how the finished characteristics of your products will be affected. The SCORPION® 2 Heat Flux Sensor measures radiant and heat fluxes at product level and displays the results in Btu/hr·ft2 or convective W/m2.

2) Humidity: Humidity is the amount of water vapor in the air. As your products bake, they use the available moisture in your oven. Without humidity, the quality and texture of your products will not turn out as expected. High oven humidity can lighten the crust color of baked goods and prevent it from burning. Lower humidity typically results in crustier bread. Global bakeries trust the SCORPION® 2 Digital Humidity Sensor, to accurately measure the absolute moisture content of the thermal environment in heating and cooling processes.

3) Air Velocity: Air velocity is the measurement of airflow inside the oven. This measurement is important because, along with other parameters, air velocity influences the coloration, texture, firmness, and baking time of your final product. Air flow can be measured and recorded with the SCORPION® 2 Air Velocity Sensor. The sensor array delivers a precise picture of airflow patterns inside the oven. The sensors collect data, at product level, as the array travels through the oven. The number of sensors varies with the width of the conveyor.

By utilizing thermal profiling technology to optimize the baking process with the help of Reading Thermal profiling systems, you will gain information you can use to make reliable data-based decisions about your processes and products. Contact us online, or call (610) 678-5890 Ext. 2 to explore our line of innovative products.