If you’re in the business of industrial baking, you know how challenging it can be to achieve consistent results. From batches that don’t bake evenly to baked goods that come out either underbaked or burnt — with no way of knowing what went wrong until after it’s too late. With increasing customer expectations for fresh, homestyle products, maintaining quality and consistency is front-of-mind for any major bakery. Using thermal profiling for baking consistency in industrial bakery ovens, bakers and line-workers can intuitively monitor, analyze, and adjust oven parameters to produce the same product with every single batch.

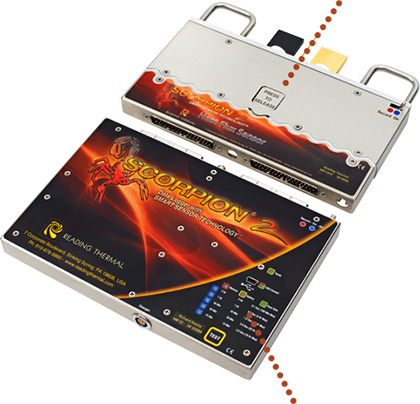

A single poorly baked batch can damage a bakery’s reputation and ultimately, their profits. That’s why the Reading Thermal’s SCORPION® 2 Profiling System is so essential for today’s bakers. This cutting-edge thermal profiling technology allows bakers to monitor baking consistency across multiple oven lines, ensuring consistently high-quality results every time. Our technology ensures bakers can track the entire baking process and make informed adjustments to temperature, airflow, and other factors to achieve the perfect results every time. Now, industrial bakeries no longer have to rely on guesswork or the human eye to create perfectly baked goods. With Thermal’s SCORPION® 2 Profiling System, they can produce consistent batches of high-quality goods with ease.

What is Thermal Profiling?

Thermal profiling is a process that uses advanced temperature measurement technology to track the performance of ovens in real-time. With this data, bakers can monitor baking consistency across multiple oven lines and make adjustments as needed to ensure consistent results. This type of thermal monitoring helps industrial bakeries create perfectly baked goods every time — no more guesswork or relying on the human eye. With this technology, line workers can make precise adjustments before and during baking to ensure every batch comes out perfect.

The establishment of a consistent thermal profile that can be used as the template for all of your bakery’s ovens. These include the oven conditions, environments, and parameters, all of which affect your baked goods. Even minor variations between each oven’s settings can have a dramatic impact on the final product, so this thermal profiling technology is essential for industrial bakeries.

The Same Products Every Time

Your bakery’s reputation hinges on the quality of your products. With Thermal’s SCORPION® 2 Profiling System, you can ensure that each batch of baked goods comes out exactly to specification — no more guesswork or trial and error. This technology allows line workers to accurately monitor oven temperature settings in real-time, making adjustments as needed to achieve consistent results across all oven lines. Now, your customers can enjoy the same delicious, freshly-baked products every time.

An Intuitive Profiling Solution

Industrial bakeries have high production output, which means to keep pace with output you need solutions that are seamless to implement. Depending on the complexity of your thermal profiling solution, that could mean extra training, hardware installation, and/or software integration. Reading Thermal’s SCORPION® 2 Profiling System makes it easy to integrate with existing ovens and offers an intuitive user interface. This makes it easy for line workers to monitor baking consistency in real-time and make adjustments as needed, minimizing downtime while mitigating risk.

For any industrial bakery, maintaining product quality is essential to success — and that means consistent baked goods every time. Working with Reading Thermal lays the groundwork for growth, using thermal profiling for baking consistency in industrial bakery ovens. If you’re interested in our tools, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.