If you are experiencing inconsistent product quality in your commercial bread baking process, monitoring oven temperature with Reading Thermal’s Scorpion® 2 Profiling System and Data Logger will give you a precise picture of what is happening inside your oven.

Reading Thermal, a Reading Bakery Systems brand headquartered in Sinking Spring, Pennsylvania, has researched and examined the commercial baking process since 1999. As a result, our team of heat transfer experts developed the SCORPION® 2 Data Logging Measurement System, now an industry standard, which measures and maps the essential baking parameters of temperature, air velocity, heat flux, and humidity.

Why Monitor Oven Temperature?

If you produce bread, artisan bread, biscuits, rolls, hamburger buns, cakes, and similar bread products, you are aware that oven temperature is responsible for physical and chemical reactions in dough/batter, and that excessively low or excessively high temperatures during baking can lead to changes in fermentation and humidity levels.

Too little heat can result in color that is too light. It can also cause the product structure to be too compact because few air bubbles developed in the baking process. This can produce a heavy and unappealing loaf with a pale or soft crust.

Too much heat coming from one direction in the oven can cause the bottoms of the loaves to burn before the crusts brown properly. The surface color will usually be too dark and the product may rise unevenly, resulting in many surface cracks.

Measuring and controlling internal food temperature is also key to achieving food safety. Validating the kill-step for your baked goods is easy with the SCORPION® 2 Profiling System and Data Logger.

Solutions for Bread & Bun Profiling

Placement of the SCORPION® 2 in the oven is critical in order to produce accurate and repeatable data collection. Unlike biscuit and cracker tunnel ovens where the equipment simply rides on the conveyor, large bread & bun ovens like BakeTech, AMF, and Turkington, require specialized carriers to provide easy loading and unloading on endless conveyor ovens and tray and grid conveyor ovens.

Long bake times and the need to produce the Bake Cycle S-Curve have also led Reading Thermal to design a set of solutions just for the Bread & Bun baker, including:

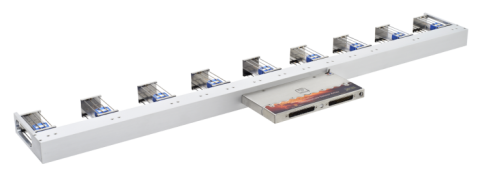

Temp+Airflow Sensor Array – The Temp+Airflow Sensor Array simultaneously profiles temperature and airflow across the width of large tray and grid conveyor ovens. The sensor array contains nine Temp+Airflow sensors spaced evenly across the length of an aluminum bar. The array comes in three sizes to match the most popular bread oven conveyor widths.

Pan+Dough Probe – Reading Thermal’s Pan+Dough Probe™ is a dual probe unit that is placed under the bread or bun dough and simultaneously captures the pan/dough interface temperature and the dough core temperature. A copper plate is placed into the pan and remains fixed at the same single point during its entire passage through the oven. The Probe provides accurate repeatable results that cannot be achieved with hand-placed thermocouples.

Reading Thermal can help you resolve temperature monitoring issues in your commercial bread baking process and ensure that you have the critical information you need to correct problems and maintain optimum conditions. Call us at (610) 678-5890 Ext. 2, or contact us online to learn more about our state-of-the-art products.