Regulating temperature and air circulation in large-scale ovens is crucial for achieving consistent and high-quality baking results in commercial baking operations. These factors directly impact product texture, appearance and overall quality. In this article, Reading Thermal experts will cover the significance of temperature and air circulation, the methods used to control these variables, and their effects on baked goods.

Temperature Control

Temperature control is one of the most critical aspects of baking, as it directly affects the chemical reactions, moisture evaporation, and physical transformations that occur during the baking process. Different types of baked goods require specific baking temperatures to achieve optimal results. For example, bread typically requires high temperatures to promote yeast activation and dough expansion, while delicate pastries may require lower temperatures to prevent over-browning or burning.

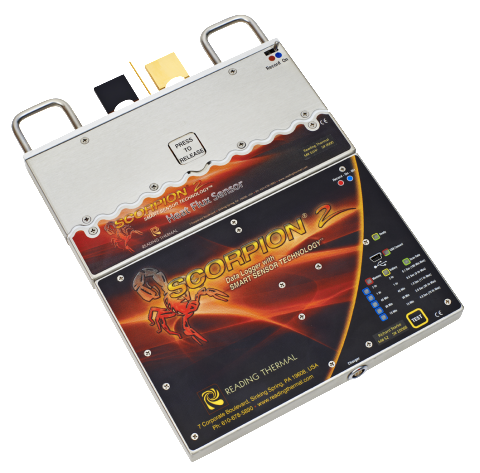

In large-scale ovens, temperature regulation is achieved through precise control of heating elements, such as gas burners, electric heating coils or steam injectors. These heating elements generate heat within the oven chamber, raising the temperature to the desired level for baking. Temperature sensors located throughout the oven monitor temperature variations and provide feedback to the oven control system, allowing for real-time adjustments to maintain consistency. Reading Thermal’s SCORPION® 2 System includes sophisticated data logging measurement tools to help you continuously monitor temperatures.

Air Circulation

Air circulation is another critical factor in large-scale ovens, as it ensures even heat distribution and promotes uniform baking results across the entire baking chamber. Our SCORPION® 2 System accurately measures air velocity, helping prevent hot spots and cold zones within the oven. This reduces the risk of uneven baking, over-browning or under-cooking. Consistent airflow also aids in moisture evaporation and crust formation, contributing to the desired texture and appearance of baked goods.

In large-scale ovens, air circulation is typically achieved through the use of fans or blowers positioned strategically within the oven chamber. These fans circulate hot air evenly throughout the oven, ensuring uniform heat distribution and promoting consistent baking results. By controlling the speed and direction of airflow, bakery operators can adjust oven settings to meet the specific requirements of different products or recipes.

One method used to regulate temperature and air circulation in large-scale ovens is the implementation of sophisticated control systems, such as the SCORPION® 2. These systems utilize advanced algorithms and sensors to monitor temperature, airflow, and other variables in real-time, allowing for precise control and optimization of baking conditions. Bakery operators can program these control systems to adjust oven settings automatically based on predefined recipes or desired baking outcomes.

Steam Injection

Some large-scale ovens are equipped with steam injection systems, which introduce controlled amounts of steam into the oven chamber. Our SCORPION® 2 Digital Humidity Sensor can help regulate humidity levels and enhance product quality. Steam injection helps prevent product dehydration, promote crust development, and improve the texture of baked goods such as bread and pastries. The SCORPION® 2 Digital Humidity Sensor helps ensure consistent performance.

Whether through sophisticated control systems, advanced airflow management techniques, or steam injection systems, maintaining precise temperature and air circulation is key to meeting customer expectations and staying competitive in the commercial baking industry.

Learn more about how Reading Thermal products assist in regulating temperature and air circulation in large-scale ovens by calling 610-678-5890 or using our online form.