Optimization of the thermal profile in your industrial ovens can improve the quality of products in your bakery production lines.

The heat transfer experts at Reading Thermal, headquartered in Sinking Spring, Pennsylvania, have studied and measured the commercial baking process for more than 25 years. We manufacture and support the SCORPION® 2 Profiling System, a baking industry standard.

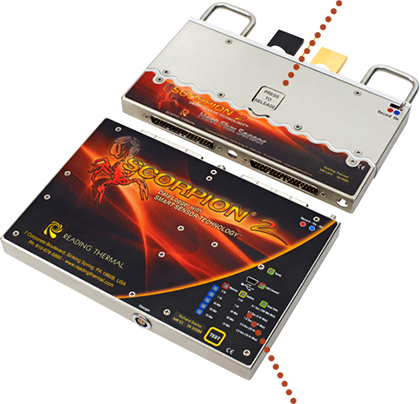

The SCORPION® 2 Data Logger is the “brain” of the profiling system. It captures and stores profile data from the Smart Sensors that can be downloaded to a computer for display and analysis. It can capture data from up to 32 sensor/input channels as fast as 10 times per second and can be saved until the user chooses to delete them.

Why Temperature Profiling is Important?

Product level temperature throughout an oven can make the difference between optimum quality and throughput – and wasteful, under-baked, or burnt product. The process of fermentation, product swelling, moisture evaporation, flavor development, and surface coloring are all time and temperature dependent. For example:

- Too little heat can cause crusts to be brittle or dry,

- Too little heat can create products that are too light in color.

- Too little heat can create a structure that is too dense.

- Excess heat can cause the bottoms of the loaves to burn before the crusts brown correctly.

- Excess heat causes moisture to evaporate too rapidly and the dough to rise unevenly.

If you produce bread, artisan bread, buns, rolls. biscuits, cakes, or other bread products, you understand that several stages of the process are temperature-dependent, including oven-spring, drying/dehydration, and color formation.

Data Logging & Analysis

The SCORPION® 2 Profiling System and Data Logger enables you to monitor actual in-process conditions and get the critical information you need to correct problems and maintain optimum process control. This powerful diagnostic tool is valued by commercial bakeries around the globe for understanding and improving bakery proofing, baking, cooling, and freezing processes, and for FSMA kill-step validation.

Following data collection, the profiles are downloaded from the Data Logger to a PC for analysis with the proprietary SCORPION® Software Version 8 (SV8), which takes data analysis to a whole new level, making it easier than ever to understand the data collected from your process.

Developed specifically to support the latest SCORPION® 2 hardware, SV8 also maintains compatibility and can be used with the older SCORPION® data loggers dating back to 1990. While significantly enhanced, it retains traditional on-screen displays so that existing SV7 Users can easily transition to SV8 without having to relearn the data analysis/interpretation process.

If you are interested in optimization of the thermal profile for your industrial bakery production lines, look no further than the state-of-the-art Reading Thermal SCORPION® 2 Profiling System and our exceptional sensors and sensor arrays. Contact us online, or call (610) 678-5890 Ext. 2 to explore our line of innovative products.