Your oven’s appetite for power can account for a significant chunk of your facility’s operating costs. But what if part of that energy is simply blowing away? When air flow inside your oven isn’t properly balanced or monitored, it can sabotage both product quality and efficiency. That’s why air flow management isn’t just a quality control issue – it’s a strategic move for cutting energy waste. Reading Thermal products for measuring and profiling air flow in industrial ovens help bakeries visualize and refine their oven environments, saving them energy and money in the process.

Inefficient Air Flow Means Wasted Energy

If your oven is pushing too much air through certain zones, or if the circulation isn’t uniform, you’re likely wasting energy in two directions. In one case, hot air accumulates where it’s not needed, overheating certain areas and prompting product inconsistencies. In another, underperforming zones struggle to transfer heat efficiently, leading operators to overcompensate by cranking up the overall temperature. Either way, energy is being burned without contributing to the core baking process.

This imbalance is often invisible to the eye. Your team may notice some loaves coming out darker or lighter than others, but they might not realize the root cause is uneven air movement. Without the ability to measure what’s really happening inside the baking chamber, there’s a good chance you’re operating with more energy than necessary just to mask an air flow problem.

Diagnosing Waste with Real-Time Air Flow Data

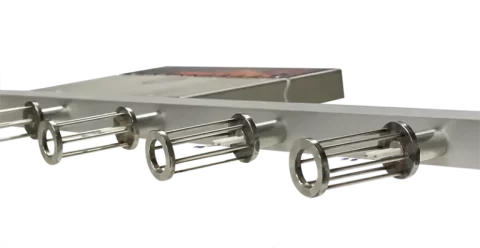

That’s where Reading Thermal’s SCORPION® 2 Air Velocity Sensor Array becomes a game changer. Instead of relying on intuition or visual cues, this tool gives you hard data about how air is moving across and through your product. It shows whether hot air is bypassing key product zones, getting trapped along the oven walls, or failing to recirculate effectively.

When you pair that data with information from our Temperature Sensor Array and Digital Humidity Sensor, you start to see the full thermal picture. You’re not just identifying temperature set points – you’re understanding how heat is transferred, how moisture behaves and how much energy is actually being used to produce consistent results. That insight allows for smarter adjustments, whether that means tuning fan speeds, rebalancing dampers, or resetting temperature zones.

Fine-Tuning Oven Performance to Use Less and Do More

Once you understand how air flow patterns affect baking performance, you can start making meaningful changes that reduce energy consumption without sacrificing quality. In fact, improving air flow often leads to faster heat penetration and more even baking, which means you may be able to reduce dwell time or slightly lower your set points while still hitting all of your product targets.

And the benefits go beyond the oven. By operating more efficiently, your facility can extend the life of key components like burners and fans, avoid overheating-sensitive products and reduce the load on exhaust systems.

Better Air Flow Equals Better Efficiency

Tools for measuring and profiling air flow in industrial ovens from Reading Thermal – especially the SCORPION® 2 platform and its modular sensor arrays – offer an inside look at energy behavior that can lead to dramatic improvements in efficiency. If energy savings are part of your production goals, start with the air that’s already moving through your system. It might be doing more harm than good, and with the right tools, you can change that. Use our online form or call 610-678-5890 for more information.