When you think about measuring air flow in industrial bakery ovens to improve consistency of baked goods, moisture might not be the first thing that comes to mind. However, moisture distribution can make or break the texture, shelf life, and even the flavor of a baked good. It influences crust development, crumb softness, and product consistency across every zone of the oven.

And air flow – how it enters, moves and exits the baking chamber – plays a pivotal role in how that moisture behaves during baking. Reading Thermal has some information on how dialing in air flow can transform baking performance, especially when paired with precise measurement tools.

The Connection Between Air Movement and Moisture Loss

Baking isn’t just about raising internal temperatures. It’s a carefully orchestrated drying process. As products heat up, water within the dough or batter begins to migrate and evaporate.

The rate at which that moisture escapes is heavily influenced by air velocity and direction inside the oven. If air is moving too fast, it can dry out the product’s surface prematurely, creating a crust that traps internal steam. If air is stagnant or unevenly distributed, certain areas may retain moisture longer than intended, leading to underbaked centers or soggy bottoms.

Even small inconsistencies in air flow can produce major quality issues. Uneven moisture distribution often shows up as patchy crusts, gummy spots or unexpected shrinkage. For multi-lane operations, inconsistent air flow can also cause baked goods from the same batch to vary significantly from one another – a frustrating outcome for any bakery focused on consistency.

Profiling Moisture Behavior with the Right Tools

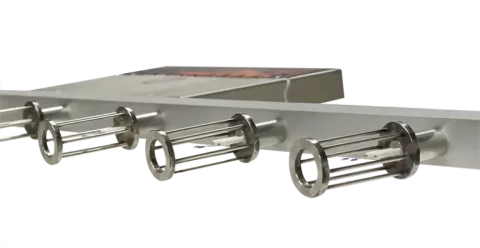

To truly understand how air flow is impacting moisture distribution, you need real data – not just assumptions. The SCORPION® 2 Air Velocity Sensor Array from Reading Thermal lets bakeries visualize exactly how air is moving across the baking chamber. This tool can detect slow zones, dead spots, or overly aggressive flows that are stripping moisture too quickly from certain areas of the product.

When combined with the Digital Humidity Sensor and Temperature Sensor Array, you gain a full-spectrum view of how water vapor behaves throughout the bake. These tools work together to help pinpoint when and where moisture is escaping, stagnating, or redistributing. That knowledge allows bakeries to adjust fan speeds, damper positions or conveyor speeds to ensure that moisture escapes in a controlled, uniform way.

Optimizing Texture and Shelf Life Through Air Flow Control

Moisture distribution doesn’t just affect how your product looks and tastes the day it’s baked – it plays a major role in how it performs days later. Products that dry out unevenly are more prone to staling or microbial spoilage. If moisture is trapped inside a sealed crust, it can create pockets of internal condensation that reduce shelf life and make packaging more challenging.

By optimizing air flow, bakeries can hit the sweet spot: enough moisture loss to build the right structure, but not so much that the interior dries out or the crust becomes brittle. Balanced air flow ensures a controlled drying curve that allows for proper texture development at every stage of the bake.

When air flow is right, moisture behaves exactly how it should. That’s when great baking becomes predictable, scalable and repeatable. Find out more about how we can help with measuring air flow in industrial bakery ovens to improve consistency of baked goods by contacting us online or calling Reading Thermal at 610-678-5890.