When it comes to operating a commercial bakery, optimizing the air flow within an industrial baking oven is one of the biggest concerns for any baker. Determining the right levels of ventilation and circulation can make all the difference in both product quality and production time. That’s why it is essential to measure and monitor the air flow within a bakery oven.

At Reading Thermal, we provide comprehensive solutions for measuring air flow in industrial bakery ovens. We understand that every baker has different needs when it comes to ventilation systems, which is why we designed our SCORPION® 2 Digital Air Velocity Sensor Array to provide a custom solution for each individual oven. When you need the most precise measurements of air velocity and flow direction, our sensor array is the perfect choice.

Why Does Air Flow Matter in Baking?

There are multiple methods through which products are baked throughout an oven cycle. While temperature is the most obvious, other parameters such as humidity and heat flux also play a large role in the quality of the finished product. One critical factor that is often overlooked is air flow within the oven; it can have an enormous effect on how quickly and evenly heat is distributed throughout the space, ultimately influencing baking time and uniformity.

When considering air flow in relation to baking, there are several key elements to consider:

- Air flow rate

- Positioning of air vents

- Direction of the airflow

Having an optimal air flow rate ensures that heat is distributed evenly throughout the oven, reducing the risk of uneven baking. The positioning of air vents can also have a dramatic effect on how efficiently heat circulates, as well as how quickly the space heats up and cools down. By modifying the direction of airflow, you can adjust how quickly heat is transferred, which is particularly beneficial for products that require a longer baking time.

As such, finding the ideal air flow settings can be the difference between a successful bake and an unsuccessful one. To ensure consistent results, it’s important to regularly monitor your ovens and make adjustments as necessary. This allows you to optimize the air flow for each product and ensure that your baked goods are of the best quality possible.

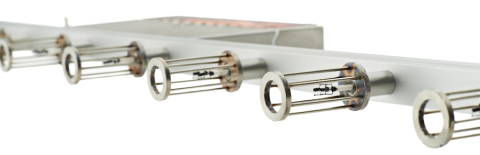

The SCORPION® 2 Digital Air Velocity Sensor Array

Our SCORPION® 2 Digital Air Velocity Sensor Array paints an accurate chart of all airflow patterns within an oven, dryer, or cooling tunnel across the entire conveyor belt or band. Given that airflow is rarely uniform within a given space, our array quickly detects any changes or irregularities in air pressure, allowing you to easily identify and adjust any faulty ventilation systems.

Air flow plays an essential role in delivering heat to the product, affecting everything from the baking time to the finished product’s appearance and taste. By using our Digital Air Velocity Sensor Array, you can easily transform your oven into a precision baking machine, ensuring that all of your products are cooked perfectly every time.

Reading Thermal takes pride in our Smart Sensor solutions, ensuring your bakery has the tools needed for precise measuring of air flow in your industrial bakery ovens. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.