Improper measurement of oven airflow and energy transfer in a bakery line can significantly impact product quality, production efficiency, and overall operational performance. In the baking industry, where precision and consistency are paramount, any deviations or inefficiencies in airflow and energy transfer can lead to adverse outcomes. The experts with Reading Thermal have some information on the downfalls of improper measurement.

Inconsistent Product Quality

One of the most immediate consequences of improper airflow and energy transfer measurement is inconsistent product quality. Inadequate airflow or uneven heat distribution within the oven can result in uneven baking, leading to products with variations in color, texture, and taste. Some areas of the baked goods may be undercooked, while others may be overbaked or burned. Inconsistent product quality not only affects consumer satisfaction but also tarnishes the reputation of the bakery and its brand.

Increased Product Waste

Improper measurement of oven airflow and energy transfer can result in higher levels of product waste. Batches of baked goods that need to meet quality standards due to uneven baking or other defects may be thrown away, leading to wasted ingredients, labor, and production time. In addition, the cost of raw materials and resources wasted on subpar products can accumulate over time, negatively impacting the bakery’s profitability and competitiveness in the market.

Reduced Production Efficiency

Inefficient airflow and energy transfer within the oven can hamper production efficiency and throughput. Uneven heating or inadequate airflow may prolong baking times, leading to slower production cycles and decreased output. Production delays can disrupt workflow schedules, increase labor costs, and affect delivery deadlines, potentially leading to dissatisfied customers and lost business opportunities. Inefficient production processes also strain resources and limit the bakery’s capacity to meet demand, hindering growth and expansion efforts.

Higher Energy Consumption

Inefficient heating and ventilation systems may require more energy to maintain desired baking temperatures, leading to increased utility bills and overhead expenses. Excessive energy usage may also expand the bakery’s carbon footprint, contributing to environmental concerns and sustainability challenges. By accurately measuring and optimizing airflow and energy transfer, bakeries can reduce energy consumption and achieve cost savings while minimizing environmental impact.

Compliance and Food Safety Risks

Inconsistent baking conditions may compromise the safety and integrity of baked goods, increasing the risk of contamination or spoilage. Failure to meet regulatory standards for food safety and quality control can result in product recalls, fines, legal liabilities, and damage to the bakery’s reputation. Proper measurement and control of airflow and energy transfer are essential for ensuring compliance with food safety regulations and upholding the trust and confidence of consumers in the bakery’s products.

Investing in accurate measurement technologies and implementing robust quality control measures are essential for mitigating these consequences and ensuring the success and sustainability of bakery businesses.

Find Out How We Can Help You Avoid These Issues

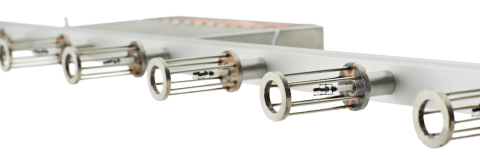

The SCORPION® 2 Digital Air Velocity Sensor Array from Reading Thermal can eliminate these and other risks of improper oven airflow and energy transfer measurement. We offer several other pieces of advanced baking technology that can significantly increase your operation’s efficiency and cost-effectiveness. You can learn more by calling 610-678-5890 or using our online contact form.