If you are interested in FSMA Kill Step Validation profiling for your commercial bakery, you can rely on the state-of-the-art Reading Thermal SCORPION® 2 Data Logger and our range of smart sensors and sensor arrays.

Reading Thermal, headquartered in Sinking Spring, Pennsylvania, has studied baking processes for 25+ years. We manufacture and support the SCORPION® 2 Profiling System, a standard in the baking industry, which provides an easy way to validate your kill step for food safety.

Kill Step Validation

Achieving food safety involves controlling internal food temperatures. The Food Safety Modernization Act (FSMA) requires commercial bakeries to validate process controls, such as thermal kill steps, in order to reduce foodborne pathogens, such as Salmonella spp, in ingredients and finished products.

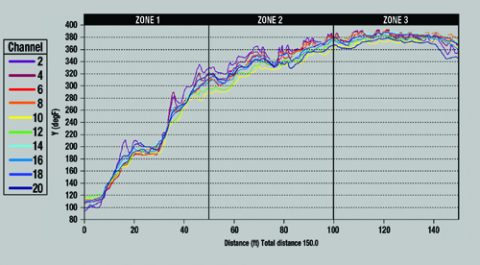

The SCORPION® 2 Temperature Sensor Array measures temperatures at the product level, in fixed positions across the conveyor, and delivers an accurate representation of what your product experiences over time. To accomplish this, we offer different types of pluggable sensors – one designed for tight mesh or solid conveyors and one for open mesh conveyors.

The sensor array is connected to the SCORPION® 2 Data Logger and travels through the oven with the product, giving you a precise picture of temperature from side-to-side and end-to-end.

After gathering the data, the SCORPION® Software (SV8) Food Safety Module simplifies the lethality calculation and then generates a comprehensive report that displays cumulative log reduction. By combining the measurements with robust data capture, the SCORPION® 2 System makes it easy to optimize your process while meeting required food safety standards.

Benefits of Validating a Kill Step:

- Helps meet safety standards (e.g., five log reduction of pathogenic coli/Salmonella) set by regulatory agencies.

- Helps achieve maximum food safety and protect consumers.

- Helps determine an effective treatment.

- Saves the food industry millions of dollars by avoiding recalls and other legal penalties caused by foodborne illness outbreaks.

- Strengthens consumer confidence.

- Supports business success.

If you are interested only in measuring temperature, consider the SCORPION® 2 LITE Temperature Data Logger. It is a low-cost alternative to the full-featured SCORPION® 2 Data Logger and simplifies the measurement of environmental and internal product core temperatures.

Reading Thermal also offers a SCORPION® Profiling Service to assist customers with problem-solving in their own facilities. We use the state-of-the-art SCORPION® Data Logging Measurement System to collect thermal profiles of temperature (air, band, product), humidity, air velocity, and heat flux. We have the ability to analyze a single line or perform multi-line comparison studies that will determine what is causing problematic processing conditions and find solutions.

Achieve maximum food safety compliance and abide by the FSMA kill step validation protocol with oven profiling systems from Reading Thermal. Get in touch with our headquarters in Sinking Spring, Pennsylvania, at (610) 678-5890 Ext. 2, or contact us online to find out more about our state-of-the-art products.