Do you run a busy commercial bakery that requires constant changes in temperatures and humidity? If so, you know that your industrial ovens need to consistently hit the same optimal baking conditions every time. But how can you ensure this is happening in a reliable way? The answer is simple: industrial oven humidity and temperature data logging, which takes the guesswork out of crafting perfect baked goods.

The most reliable industrial oven humidity and temperature data logging system comes from Reading Thermal. Our products provide accurate, real-time thermal readings that can be monitored remotely for greater convenience. With our advanced technology, you can stay up to date with the conditions inside your industrial ovens even if you’re not in the bakery. This helps ensure that all of your products are consistently baked to perfection and your customers always get the best results.

What Role Does Humidity Play in the Baking Process?

Most people don’t realize the importance of humidity in baking. When a recipe calls for a certain temperature, it also usually requires the oven to be at a specific moisture level as well. This is because different types of pastry dough require different amounts of moisture in order to rise properly and bake evenly.

For example, pastry dough usually contains a high amount of fat. This makes the dough lighter and flakier, but if there is too much moisture in the air when baking, it can cause the dough to become heavy and dense. On the other hand, cakes require more moisture than pastries do in order to be light and fluffy. If the humidity level is too low when baking a cake, it can result in a dry and crumbly texture.

Humidity also affects how quickly food cooks. If the air is too humid, it will take longer for heat to penetrate into the center of your baked goods. On the other hand, if there is not enough moisture in the air, the food will cook faster than it should, resulting in an undercooked or burnt product.

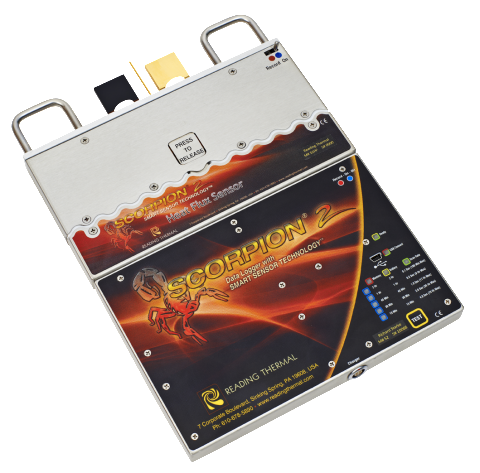

Like any baking parameter, humidity can be difficult to control if you don’t have the right tools at your disposal. Utilizing our SCORPION® 2 Digital Humidity Sensor, you can easily monitor the humidity in your oven and maintain consistent results. With its precise measurements and user-friendly interface, it takes all the guesswork out of baking so that you can achieve consistent results every time.

What Role Does Temperature Play in the Baking Process?

Temperature is an essential element in the baking process. It helps regulate the time and moisture available, so that the consistency of whatever it is you are baking will be just right. For instance, if a recipe calls for soft-baked cookies or flaky pie crusts, they can both benefit from a lower temperature setting. At too high of a temperature, these treats can become dry and brittle, whereas a lower temperature will help them remain soft and delicate. Leveraging our SCORPION® 2 Temperature Sensor Array helps with that.

Fundamentally, both humidity and temperature are sensitive components in the baking process. When you get both of them right, they work together to create a delicious end product that is just as much an art as it is a science. In order to get the perfect results, all you need is an industrial oven humidity and temperature data logging solution to compile all your measurements for easy analysis. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.