Nothing is quite like the smell of freshly baked goods wafting through a bakery. For owners and operators, that delicious aroma results from precision in baking – and precision starts with accurate measurements of factors like temperature and humidity throughout the industrial process. High-temperature humidity sensors for industrial baking are an invaluable tool to ensure your recipes turn out perfect every time.

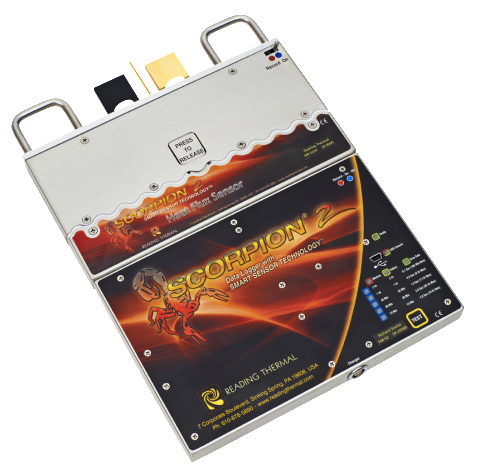

And when choosing the right provider for these sensors, there’s no better choice than Reading Thermal. Reading Thermal has been a trusted name for decades, providing top-of-the-line temperature and humidity measurement solutions for industrial baking. With nearly 25 years of experience, our team understands the unique challenges bakeries face and the importance of precise measurements in achieving consistent, high-quality results. We pride ourselves on offering cutting-edge technology and personalized customer service to ensure our clients have the best experience possible. Our sensors are designed to withstand high temperatures and harsh environments, making them perfect for industrial baking.

The Importance of Humidity in Industrial Baking

Humidity plays a crucial role in the baking process; without it, our beloved baked goods wouldn’t be the same. During baking, humidity helps determine how much moisture is retained in the product, directly affecting its shelf life. Too little humidity can result in a dry and crumbly texture, while too much humidity can cause mold growth and spoilage. Therefore, controlling humidity levels is essential for ensuring food safety and extending the shelf life of baked goods.

But it’s not just about preservation – humidity also contributes to the overall quality and appearance of baked goods. It provides products the flexibility to prevent cracking, ensuring a perfectly smooth surface. Additionally, proper humidity levels help give products a glossy crust, adding to their aesthetic appeal.

Finally, humidity is critical in killing pathogens that can cause foodborne illnesses. High temperatures and low humidity levels work together to create an inhospitable environment for these harmful microorganisms, ensuring the safety of consumers.

Baking is a science, and humidity is a critical variable that, if untended to, can make or break the final product. That’s why investing in high-temperature humidity sensors for industrial baking is a wise choice for any bakery looking to achieve consistent, high-quality results.

Measuring Dew Point Temperature, Absolute Humidity, and Relative Humidity

At Reading Thermal, we offer a range of high-temperature humidity sensors to meet our clients’ specific needs and requirements. Our sensors can measure dew point temperature, absolute humidity, and relative humidity – all crucial parameters in the baking process.

Dew point temperature is the temperature at which water vapor condenses into liquid form. In baking, this is important as it helps determine the moisture content in the air, which affects how much moisture a product can absorb.

Absolute humidity refers to the amount of water vapor in the air, measured in grams per cubic meter. This measurement is essential for determining how much moisture products can absorb during baking.

Relative humidity, however, measures the percentage of water vapor in the air compared to the maximum amount of water vapor it can hold at a given temperature. This measurement is critical for controlling humidity levels and ensuring consistency in baking results.

There’s no better provider than Reading Thermal for the greatest level of precision with high-temperature sensors for industrial baking. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.