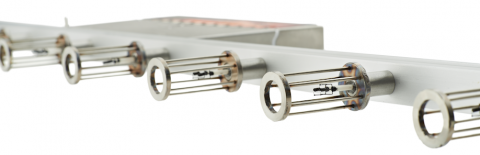

The SCORPION® 2 Digital Air Velocity Sensor Array from Reading Thermal can play a key role in ensuring the even distribution of airflow in industrial oven systems. It contains multiple sensors strategically placed throughout the oven chamber to monitor various parameters such as temperature, humidity, and airflow velocity. By continuously collecting data from these sensors, the oven system can adjust airflow patterns and temperature profiles to achieve uniform heating and baking of products. Here’s a closer look at how this product can help ensure your baked goods continue to be of the highest quality.

Monitoring Airflow Velocity

Sensory arrays measure airflow velocity at different points within the oven chamber to assess the distribution of air currents. Variations in airflow velocity can result in uneven heating and baking of products, leading to inconsistency in product quality. By analyzing sensor data, the oven system can identify areas of low or high airflow velocity and adjust damper settings or fan speeds to achieve a more uniform airflow distribution. This ensures that all product parts receive adequate heat transfer, resulting in consistent baking and optimal product quality.

Detecting Hotspots and Cold Spots

Hotspots and cold spots within the oven chamber can occur due to uneven airflow distribution or insulation issues. Hotspots may result in overbaked or burnt areas on the product, while cold spots may lead to undercooked or raw portions. By identifying these temperature variations, a sensor array can help the oven system implement corrective measures such as redistributing airflow or adjusting temperature settings. This ensures that products are uniformly baked throughout, eliminating quality defects and reducing product waste.

Optimizing Temperature Profiles

Sensory arrays provide real-time data on temperature profiles across the oven chamber, allowing the oven system to optimize heating patterns for consistent baking. By monitoring temperature gradients and fluctuations, the system can adjust heating elements or burner settings to maintain desired temperature levels throughout the baking process. This prevents products from overheating or underheating and ensures that they are baked evenly from edge to center. Optimizing temperature profiles also helps reduce energy consumption and operating costs by minimizing unnecessary heat loss or overcompensation.

Facilitating Automated Control Systems

These integral components of automated control systems in industrial ovens enable precise and adaptive control of airflow distribution. By integrating sensor data with feedback loops and algorithms, the control system can dynamically adjust airflow patterns and temperature settings in response to changing conditions within the oven chamber. This ensures continuous optimization of baking parameters to achieve uniform product quality while minimizing manual intervention and human error. Automated control systems equipped with sensory arrays improve process efficiency, consistency, and reliability, resulting in higher productivity and throughput.

Enhancing Quality Assurance

Sensory arrays also contribute to enhanced quality assurance. Consistent airflow patterns produce consistent product quality, reducing defects, rejects, and customer complaints. With reliable monitoring and control of airflow distribution, bakery operators can have confidence in the reliability and repeatability of their baking processes, leading to improved product consistency, customer satisfaction, and brand reputation.

The advanced SCORPION® 2 Digital Air Velocity Sensor Array from Reading Thermal helps bakery operators achieve optimal baking results and maintain a competitive edge in the market. You can learn more by calling us at 610-678-5890 or contacting us online.