Baking is an art and a science, with the perfect balance of temperature and timing required to produce high-quality goods. However, getting this right in an industrial bakery setting can be tricky, as ovens need to work quickly and consistently to meet production goals. Enter thermal profiling: a method used by commercial and industrial bakeries that helps ensure your baked goods turn out perfectly each time. This approach analyzes temperatures throughout the baking process – from pre-heat to bake times – to determine when peak performance has been reached for optimal baking conditions.

Reading Thermal’s profiling systems can help you achieve this goal. With advanced sensors, these systems measure temperatures in both air and dough during baking, giving you a real-time look at the baking process. This data is then analyzed to determine where adjustments might need to be made to ensure consistent results – such as slowing down the bake time to get a more even heat distribution throughout the oven. The end result? Perfectly baked goods every time! Not only does thermal profiling reduce baking inconsistency and waste, but it also helps save time by allowing you to adjust your baking parameters for maximum efficiency.

What Is Thermal Profiling?

Thermal profiling provides visibility into the baking process, allowing you to adjust your baking parameters for the best results. With thermal profiling, you can monitor the temperatures of each component throughout the oven – including baskets, racks, and trays – at different times during baking. This enables you to fine-tune settings and achieve consistent results time after time. Bakers can use this information to determine optimal bake times, temperatures, and other parameters that will help them consistently produce high-quality baked goods with minimal waste.

Each baking parameter must be monitored, analyzed, and adjusted to ensure that your baked goods receive the correct treatment for optimal results. This often proves to be a bigger challenge than it’s given credit for. For commercial and industrial bakeries that operate with numerous ovens, chances are that every oven environment is different. Different oven models require different settings, making it difficult to ensure consistent baking results across all ovens, given that no two oven environments will be identical. Generating thermal profiles according to the unique characteristics of each oven can help you achieve the most consistent and optimal baking results.

Analyzing the Results for Precise Adjustments

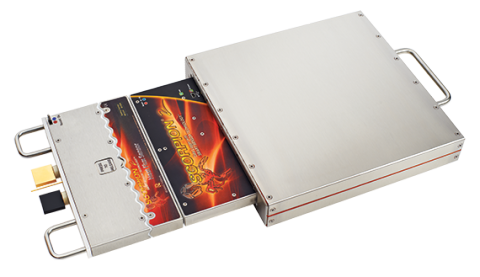

An accurate thermal profile is only possible when you measure and monitor all the baking parameters available. Reading Thermal’s SCORPION® 2 Profiling System uses advanced sensors to measure and monitor multiple variables at each point during the baking process. This data provides real-time insight into your oven conditions, compiling data on air velocity, humidity, temperature, and heat flux throughout the baking process.

All data gathered by our Smart Sensors is contained and stored in our SCORPION® 2 Data Logger, which can be downloaded onto a remote computer later and processed through our proprietary SCORPION® Software Version 8 (SV8). This software provides advanced data analysis, allowing you to compare various baking cycles and make precise adjustments based on your specific oven environment.

With your oven data visualized in real-time, determining optimal baking conditions using thermal profiling is easier than ever. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.