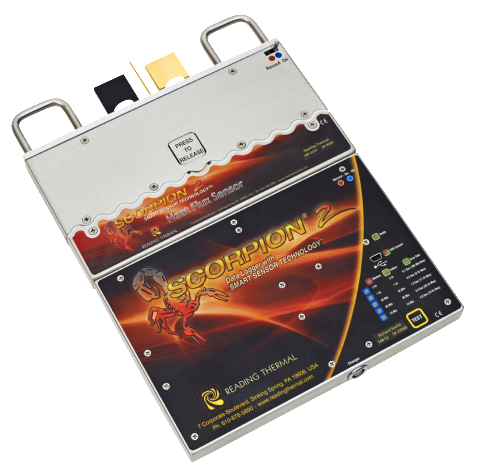

Reading Thermal provides the best data logging solutions for monitoring oven temperatures in industrial bakeries. By capturing critical data in real time, data loggers empower bakeries to optimize production processes, ensure product consistency and maintain compliance with safety standards.

However, to fully leverage the potential of data logging solutions, you need to understand the key metrics they track and how those metrics impact your operations. Focusing on the right data points can make the difference between simply collecting information and driving meaningful improvements.

Temperature

Temperature is arguably the most important metric in any baking process. It directly influences the texture, flavor, and appearance of baked goods. Monitoring oven temperatures with data loggers ensures consistency across batches by identifying fluctuations or hot and cold spots that can lead to uneven baking.

With precise temperature data, you can adjust oven settings to maintain the optimal range for each product. For example, artisan bread requires specific temperature profiles to achieve the perfect crust and crumb.

Reading Thermal data loggers allow you to capture these profiles and replicate them consistently. In addition, tracking temperature ensures energy efficiency by identifying areas where ovens may be over- or under-heating, helping to reduce energy waste without compromising quality.

Humidity Levels

Proper humidity levels help control the moisture content in dough, affecting texture, shelf life and overall quality. Data loggers equipped with humidity sensors monitor these levels throughout the baking process, providing insights that help bakers fine-tune conditions.

Maintaining the right humidity is essential for preventing issues like cracked crusts or overly dry products. By tracking this metric, bakeries can ensure their goods retain the desired moisture balance, resulting in consistent quality that meets customer expectations.

Airflow

Airflow within an oven significantly impacts baking outcomes, as uneven airflow can cause inconsistent heat distribution. Data loggers help track airflow patterns to ensure heat circulates evenly across the oven chamber. This is particularly important for large-scale commercial ovens with multiple zones, where variations in airflow can lead to overcooking in one area and undercooking in another.

Analyzing airflow data allows you to identify inefficiencies and adjust oven design or operation to improve performance. It also helps reduce waste by minimizing the chances of defective batches caused by uneven baking.

Energy Usage

Energy consumption is a key metric for cost management and sustainability in commercial baking. Data loggers track energy use in real time, providing actionable insights into where and how energy is being consumed. This information enables bakeries to identify inefficiencies, such as ovens that consume more power than necessary or processes that could be optimized for better energy performance.

Monitoring energy usage also supports compliance with sustainability goals and regulatory requirements. Reducing energy consumption allows bakeries to lower operational costs while demonstrating their commitment to environmentally friendly practices.

Time

Time is another critical metric in baking, as it directly impacts efficiency and productivity. Data loggers capture timing data for various stages of the baking process, from preheating ovens to the duration of each bake cycle. Tracking this metric helps bakeries identify opportunities to streamline workflows and reduce downtime.

For example, if data shows that preheating takes longer than expected, adjustments can be made to optimize oven readiness. Similarly, analyzing bake times can help ensure products aren’t overcooked or undercooked, leading to consistent results and minimal waste.

See for yourself why you should consider data logging solutions for monitoring oven temperatures in industrial bakeries from Reading Thermal. Learn more by contacting us online or calling 610-678-5890.