Bakers know that the quality and taste of their products are largely dependent on moisture and humidity levels. High humidity can cause slow baking times, furniture shrinkage, mold growth, and other issues that lead to sub-par results. Industrial bakeries need to be particularly careful about controlling temperature and humidity in ovens in order to protect the product they produce – it’s essential for success.

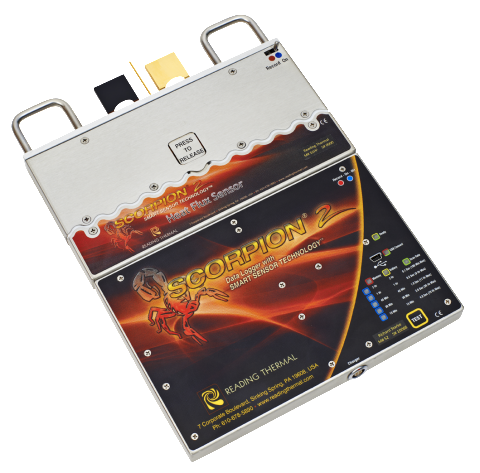

Data logging is at the core of Reading Thermal’s SCORPION® 2 Profiling System. While the Smart Sensors we manufacture are renowned as industry staples, they don’t mean much without the SCORPION® 2 Data Logger attached. The SCORPION® 2 Data Logger gathers and stores temperature, humidity, air velocity, energy transfer, and heat flux data from our Smart Sensors, providing an unprecedented level of accuracy. With its high-resolution sensors, our Data Logger ensures that the data it collects is as precise and accurate as possible – meaning you can trust the results.

Getting the Most Out of the Baking Process

Baking isn’t a process you can wing and get a perfect result. Every step matters and, and when every step matters you need to pay attention to the intricacies of your baking parameters to ensure they’re within your expectations. Measuring the temperature and humidity is straightforward, all you need to do is run your SCORPION® 2 Digital Humidity Sensor and Temperature Sensor Array through the baking process and let them do the work. Of course, that data isn’t useful if you don’t have a way to create a profile out of it and analyze it later.

The Brain of the SCORPION® 2 Profiling System

The SCORPION® 2 Profiling System is a combination of Smart Sensors designed to paint the most accurate image of every baking parameter used in your baking process. At the core of them all is the SCORPION® 2 Data Logger.

Every sensor starts the process by connecting to the Data Logger. The Data Logger records, saves, and creates a profile using all the metrics gathered throughout the data gathering process. These profiles are then downloaded later to a computer of your choice for thorough analysis with our SCORPION® Software Version 8 (SV8).

Nothing in the Profiling System works without the Data Logger. It can capture data from up to 32 sensor/input channels as fast as 10 times per second, create multiple profiles before downloading, and uses an intuitive interface so that any worker in your bakery can use it with minimal training. Fundamentally, it makes data collection while baking a snap – and with our high-resolution sensors, you can rest assured that the data it collects is accurate.

How Does This Help Your Baking Process?

With a data logging system like the SCORPION® 2 Profiling System, bakers can easily track fluctuations in baking parameters like temperature and humidity during every stage of the baking process. This allows them to make adjustments on-the-fly to ensure that their product is baked to perfection, while avoiding expensive mistakes.

At Reading Thermal, we pride ourselves on providing innovative solutions to help bakers produce the highest quality products. With the SCORPION® 2 Profiling System and its Data Logger, data logging for monitoring temperature and humidity in ovens has never been easier. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.