Baking is an art and a science, and with any scientific process, temperature control plays an integral role in the uniformity of your products. Industrial bakeries not only have to produce consistent outcomes at a regular pace, but they also have to do so using multiple ovens of different models from separate manufacturers. Every oven environment is unique, which makes aligning oven conditions to bake products at the same temperature an essential step in achieving consistent results. Controlling temperature uniformity in industrial ovens is where Reading Thermal’s solutions excel.

Reading Thermal has been manufacturing and developing industry-leading baking technologies for over thirty years. We offer superior solutions for measuring temperature in industrial ovens, allowing bakeries to bake high-quality products with greater consistency and capacity. Our advanced equipment works by accurately measuring the location of the thermal gradient in an oven’s chamber and making adjustments accordingly, allowing for precise control of temperature in all of your ovens.

Measuring the Four Key Oven Parameters Simultaneously

Heat flux, air velocity, temperature, and humidity are the four key oven parameters that must be monitored and controlled to achieve uniform temperatures throughout an industrial oven. Any variation in these factors can ruin a batch of baked goods, compromising their structure, flavor profile, texture, and safety in consumption. Measuring these parameters often requires multiple dedicated Smart Sensors running through the baking process, which is vital to securing food quality and is time-consuming.

Most solutions for compiling this data with Reading Thermal’s SCORPION® 2 Profiling System involve plugging a modular sensor with our SCORPION® 2 Data Logger, which runs along a full-load baking cycle to track and store environmental factors. This means conducting a comprehensive examination of your ovens requires multiple passes before your bakers have a complete thermal profile. Reading Thermal has the technology to streamline and optimize the data collection process.

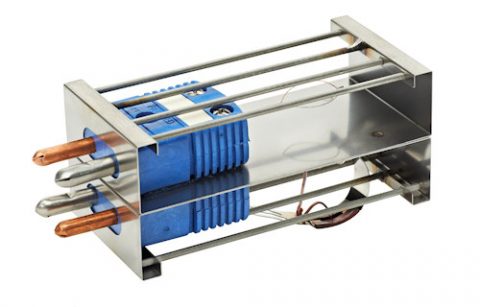

The Reading Thermal R&D Smart Sensor is designed to capture and characterize each oven parameter into a single unified profile. This means you can monitor all four parameters simultaneously and accurately, eliminating the need for multiple passes and saving you time collecting data. Our SCORPION® 2 Smart Sensor is a powerful tool that allows bakeries to quickly detect where changes are needed to increase temperature uniformity, resulting in better quality products while speeding up production times.

Modernizing Oven Profile Capture and Analysis

Some key advantages of monitoring all four oven parameters simultaneously include the following:

- Reduced baking cycle time and cost

- Increased accuracy and precision of data collection

- Improved product quality

- The ability to identify potential problem areas in an oven quickly

- Greater consistency across batches and production runs

Industrial bakeries generally operate with multiple ovens manufactured by different brands. Since they are different models, their oven environment conditions will be different too. This means that with traditional data collection methods, each oven has to be monitored separately and adjusted manually. Using the R&D Smart Sensor captures all the necessary information to make precise adjustments in a single pass, allowing you to visualize each unique oven profile via our SCORPION® Software (SV8), letting you know exactly what is happening in your ovens.

The only feasible way to control industrial ovens’ temperature uniformity is by analyzing and comparing all relevant data to determine where adjustments are needed. Reading Thermal can help make that happen. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.