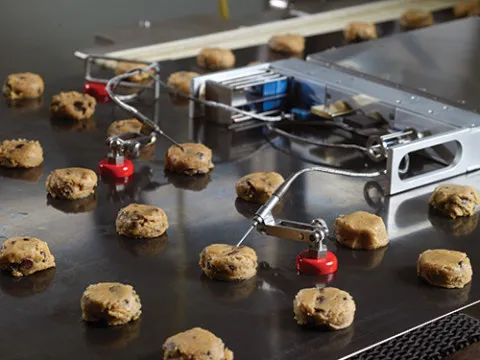

When choosing the best thermal profiler for your bakery oven, don’t discount the importance of measuring heat flux. This controls the “pace and pressure” of the bake – how quickly energy is being delivered to the dough or batter as it travels through the oven. When you can see that energy transfer directly, you’ll tune faster, troubleshoot smarter and lock in the color, lift and texture your customers expect. Reading Thermal’s SCORPION® 2 Heat Flux Sensor rides with your product and makes that invisible energy visible, in units that bakers can use batch after batch.

What Heat Flux Actually Tells You

Heat flows to your product in a few ways – primarily convection from moving hot air and radiation from hot surfaces. A heat-flux sensor captures the combined effect at product level, which is what truly shapes crust formation, moisture loss and internal set. It’s a much more direct signal than air temperature alone. You can immediately see when a zone is pushing too hard, when a belt lane is being starved or when a recipe change needs a gentler handoff between zones.

Reading Thermal designed the SCORPION® 2 Heat Flux Sensor specifically for this reality of bakery lines, converting what the product feels into readable profiles you can compare, store and repeat.

Fix Problems Faster And With Less Guesswork

If you’ve ever chased pale centers with darker edges, you know how long trial-and-error can take. With heat-flux profiles, you’ll see the exact moment and location energy delivery goes off script. Maybe a radiant-heavy zone overdrives the edge lanes, or a draft near the outfeed steals energy at the last minute. By pairing the Heat Flux Sensor with the SCORPION® 2 Data Logger, you can capture a full, product-level map under real production loads and adjust dampers, set points, or line speed with confidence rather than hunches.

Build Consistency Across Ovens, Lines And Seasons

Moving an SKU to a second line? Launching a plant-to-plant transfer? Heat-flux profiles give you a “golden” energy signature to replicate, even when two ovens can’t run the same air temperatures or velocities. Reading Thermal’s SCORPION® 2 Profiling System brings heat flux into the same workflow as temperature, airflow and humidity, so you can overlay runs and confirm you’re delivering the same baking energy – even if your settings differ. That makes scale-up and seasonal tuning a whole lot smoother.

See The Whole Story By Pairing Sensors

Heat flux is powerful on its own, and it’s even better when you connect it to airflow, temperature, and humidity data. Reading Thermal’s Digital Air Velocity Sensor Array shows how air actually moves across the band, the Temperature Sensor Array captures air and band temperatures at product level, and the Digital Humidity Sensor reveals when moisture spikes are changing how energy reaches the product. When those profiles line up, the “why” behind color shifts and texture changes becomes obvious – and fixable.

Practical Ways To Start Using Heat-Flux Data

If you’re new to profiling, begin by capturing a few “known good” runs with the SCORPION® 2 Heat Flux Sensor and protect your logger with the appropriate Thermal Barrier for your dwell times and temperatures. Those runs become your reference for startups, changeovers, and maintenance checks. Over time, you’ll spend less effort chasing set points and more time hitting quality specs the first time.

Call Reading Thermal at 610-678-5890 or use our online form for more information on choosing the best thermal profiler for your bakery oven.