If you’re a storeowner or industrial baker, complying with the Food Safety and Modernization Act (FSMA) is likely a priority for your business. While FSMA outlines various guidelines for food safety requirements, one of the most critical components it recommends is baking kill-step validation for FSMA compliance. An effective validation process will help ensure FDA compliance with key FSMA rules and guarantee healthier products and reduced risk to your customers.

With over 25 years of experience in the industry, Reading Thermal is one of the most reputable brands available for determining baking kill-step validation for FSMA compliance. Calculating the kill-step of the baking process is a challenge in and of itself, and it’s one bakeries all across the nation have to meet if they hope to retain a sterling reputation while satisfying FSMA regulatory standards. With the help of the SCORPION® 2 Data Logger and proprietary SCORPION® Software Version 8 (SV8), this calculation is intuitive, painless, and streamlined for maximum efficiency without compromising the integrity of the results.

What Is the Baking Kill-Step?

The baking kill step is a crucial component of ensuring FSMA compliance. It is the point in the cooking process at which the baked goods have reached a temperature that eliminates potential health risks. For example, if you’re baking bread, this kill-step temperature would be over 160°C (320°F) to ensure that any bacteria present has been destroyed and is safe for consumption.

It’s critical to note that the kill step for every baked good will be slightly different. Whether it be crackers, breads, pastries, or other baked goods, the temperature and time required to reach the kill step may differ. By extension, your understanding of your oven environments and conditions, such as humidity levels, temperature, energy transfer, and air velocity, are the core factors determining whether your ovens are achieving the baking kill-step consistently and accurately.

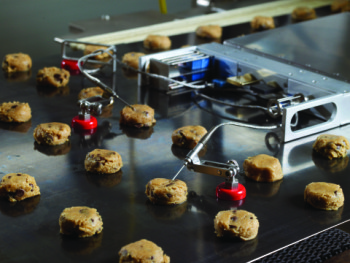

Utilizing the SCORPION® 2 Data Logger and SV8 software, you can accurately measure and record these temperatures during each cycle within your bakery ovens to determine when products are safe for distribution.

SCORPION® 2 Data Logger

Reading Thermal’s SCORPION® 2 Data Logger is an automated data acquisition system that collects, stores, and displays real-time baking temperatures in a graphical format. With its high-temperature sensors that can measure up to 350°C (662°F) accurately, this device is the perfect tool for bakeries looking to achieve FSMA compliance while staying within their budgetary constraints.

SCORPION® Software Version 8 (SV8)

The accompanying software package, SCORPION® Version 8 (SV8), makes monitoring data loggers on site and remotely via any network or internet connection easy. It also offers an intuitive data logging dashboard allowing users to view temperature trends throughout each cycle and create detailed reports for analysis and archival purposes. All data, measured at the product level, can be used to calculate the baking kill step quickly and easily via our proprietary software, optimizing the baking process to meet compliance standards easily.

Ultimately, Reading Thermal’s suite of products provides an incredibly comprehensive and cost-effective solution for calculating the baking kill step with FSMA compliance in mind. From automated data acquisition systems to powerful software packages, these tools provide bakeries with the means necessary for achieving optimal levels of food safety without compromising your budget or quality standards. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.