In order to maintain consistent quality of your bakery products, it is necessary to perform periodic oven calibration. The state-of-the-art Reading Thermal SCORPION® 2 Profiling System with Temperature Sensor Array can help.

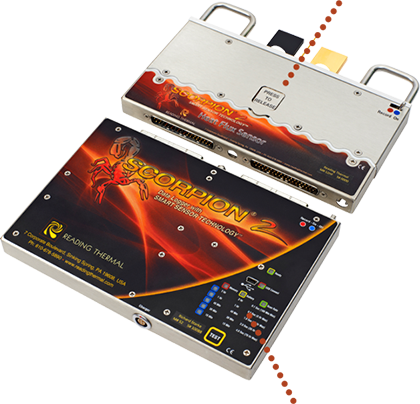

Reading Thermal, a Reading Bakery Systems brand, has focused on studying the commercial baking process for more than 25 years. We manufacture and support the SCORPION® 2 Profiling System and Data Logger which measures and maps the key baking parameters of temperature, air velocity, heat flux and humidity.

The SCORPION® 2 enables you to monitor actual in-process conditions and get the critical information you need to correct problems and maintain optimum process control.

Measure Baking Parameters

Temperature: You may think that a slight temperature difference of five to ten degrees Fahrenheit seems small, but this is enough to overcook or undercook your baked goods. Temperatures that are too low or too high can lead to changes in fermentation and humidity levels and undesirable variations in surface coloring, texture, and flavor. The SCORPION® 2 Temperature Sensor Array measures the temperature at the product level, in fixed positions across the conveyor, and provides you with an accurate representation of what your product experiences over time.

Air velocity: Oven air velocity is the measurement of airflow inside the oven. Measuring oven air velocity is critical because it influences the texture, coloration, firmness, and baking time of the final product. Oven air velocity can be measured and recorded with the SCORPION® 2 Air Velocity Sensor which delivers a precise picture of airflow patterns inside the oven from side to side and end to end. Air Velocity Profiles will help you spot airflow differences between baking zones, concentrated air velocities on isolated parts of the conveyor, and unwanted air currents at the entrance or exit of the oven that result in inconsistent baking.

Heat flux: Oven heat flux refers to the amount of energy transferred per unit area per unit time from or to a surface. It is the best non-intrusive indicator of oven performance during baking in terms of the product. The characteristics of specific products are defined by the amount and type of heat applied to the product during the baking process. The differences explain why one oven bakes differently than another. And analyzing and controlling these differences are critical to understanding how the finished characteristics of a product will be affected. The SCORPION® 2 Heat Flux Sensor measures convective and radiant heat fluxes at product level and displays the results in Btu/hr·ft2 or W/m2.

Humidity: Humidity is the amount of water vapor in the air. As your products bake, they use the available moisture inside the oven. Without humidity, the quality and texture of your products will not turn out as expected. The SCORPION® 2 Digital Humidity Sensor measures the absolute moisture content of the thermal environment in both heating and cooling processes. The sensor travels through the oven with your product, yielding a precise profile of moisture experienced by the product.

When your industrial bakery oven needs calibration, consider the innovative SCORPION® 2 Profiling System from Reading Thermal. Contact us online or call us at (610) 678-5890 Ext. 2 to learn more.