Chances are you already know just how important heat is to producing a quality product. Many aspects go into ensuring that each batch comes out optimally cooked — but one often overlooked factor in this process is airflow profiling. Airflow profiling can help your bakery produce consistent, delicious results every time without sacrificing productivity or straining your resources. How your oven’s heat is distributed and circulated is a crucial element in achieving this goal, and here’s where a partnership with Reading Thermal can make all the difference.

Essentially, you need to be able to precisely calculate your airflow conditions within your ovens before making changes and improvements. This is where a partnership with Reading Thermal comes into play, as we have the technology and expertise to help you achieve this crucial step. With our state-of-the-art equipment and experienced team, we can provide accurate readings of your oven’s air flow profile, allowing you to make informed decisions on optimizing your baking process.

The Importance of Air Flow Profiling

Industrial bakery ovens are not just about getting high temperatures or even heat distribution. Airflow profiling focuses on understanding how air moves throughout your oven and its impact on the baking process. This means determining your product’s ideal airflow pattern, temperature, and air velocity. It can lead to shorter bake times, uniform browning, reduced energy consumption, and higher-quality products.

Every oven’s airflow is different. Radiant ovens deliver air from the moving conveyor, exhaust system, and natural combustion air currents. Convection ovens recircle air primarily from the air distribution plenums. How your delivery method interacts with your products, how air is distributed, what currents they go through, and how fast the air travels all impact how they affect your products.

The SCORPION® 2 Digital Air Velocity Sensor Array

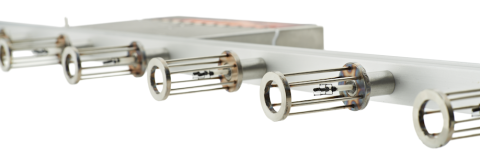

Our SCORPION® 2 Digital Air Velocity Sensor Array is designed to give as clear a picture as possible of your oven’s air flow from side to side and end to end. Coupled with our SCORPION® 2 Data Logger, all your line workers need to do is let it run through an oven cycle and analyze the results afterward.

The SCORPION® 2 Digital Air Velocity Sensor Array leverages individual sensor modules using thin-film platinum RTD hot-wire anemometers to measure your oven’s airflow. In addition, our technology can self-adjust, compensating for high or low-temperature environments on the fly.

This solution is highly efficient and easy to use, as no wires or connections are required during the baking process. The sensor array collects real-time data on air speed, direction, and temperature, providing valuable insights into your oven’s performance.

Partnering with Reading Thermal

Our team at Reading Thermal has over three decades of experience in helping industrial bakery ovens achieve optimal air flow and productivity. With our expertise and cutting-edge technology, we can provide you with customized solutions tailored to your unique needs.

Don’t underestimate the role that airflow profiling plays in creating consistent, high-quality baked goods. When you need accurate airflow profiling for industrial bakery ovens, there’s no better provider than Reading Thermal. If you’re interested in our services, call (610) 678-5890 Ext. 2 or contact us online for more details about our innovative products.