The SCORPION® 2 Digital Humidity Sensor provides a better way to measure humidity in your oven, proofer, dryer and cooling tunnel. This breakthrough design provides a more accurate and reliable way to measure the absolute moisture content of the thermal environment. The sensor contains a proprietary humidity sampling system with patented Anti-Saturation Technology™ that allows measurements in high temperature and very high dew point processes.

15 Reasons to Buy or Upgrade to the Digital Humidity Sensor:

- Compatible with existing SCORPION® 2 Data Loggers

- Anti-Saturation Technology™ allowing measurements in steam conditions

- Unaffected by combustion gases in the baking chamber (DGF Ovens)

- Single sensor for low temp (%RH) and high temp (Absolute Humidity) applications

- % Moisture by Volume, Air Temp, Dew Point Temp and %RH displayed

- Dew Point measurements from 32°F (0°C) to 212°F (100°C)

- Relative Humidity measurement from 0% to 100% RH

- Two product probe inputs for product core temperature measurements

- Document humidity during Kill Step Validation

- No preheating required

- No special thermal barriers needed

- Increased dwell time

- Free software upgrade

- User friendly ready light

- Compatible with 32mm tall systems

Technical Recommendation

by Bill Hagan

Bill Hagan, technical sales manager for AB Mauri North America, has been profiling ovens, proofers and coolers using the SCORPION®2 Digital Humidity Sensor. Mr. Hagan said that being able to measure humidity throughout the entire baking process, particularly in the oven, allows him to give bakers information that was previously not possible. He further incorporated AB Mauri’s knowledge base to assist and utilize the sensor for use in bread and roll production.

Bill Hagan, technical sales manager for AB Mauri North America, has been profiling ovens, proofers and coolers using the SCORPION®2 Digital Humidity Sensor. Mr. Hagan said that being able to measure humidity throughout the entire baking process, particularly in the oven, allows him to give bakers information that was previously not possible. He further incorporated AB Mauri’s knowledge base to assist and utilize the sensor for use in bread and roll production.

“Data from oven profiling provides absolute humidity measurements verifying steam applications and proper oven exhaust settings. Analysis of proofer data indicates relative humidity throughout the process, allowing the proper settings for optimal proof which yields the desired dough piece texture entering the oven,” Hagan said. “Profiling air-conditioned bread and bun coolers displays relative humidity through the cooler. This data can indicate too much evaporation during the cooling process, thereby drying out finished product prior to being packaged.”

Mr. Hagan recommends the SCORPION®2 Digital Humidity Sensor as an extremely versatile instrument used to document, troubleshoot and improve quality of the complete baking process.

Humidity Sensor:

Humidity Sensor:

NEW Digital vs. OLD Analog

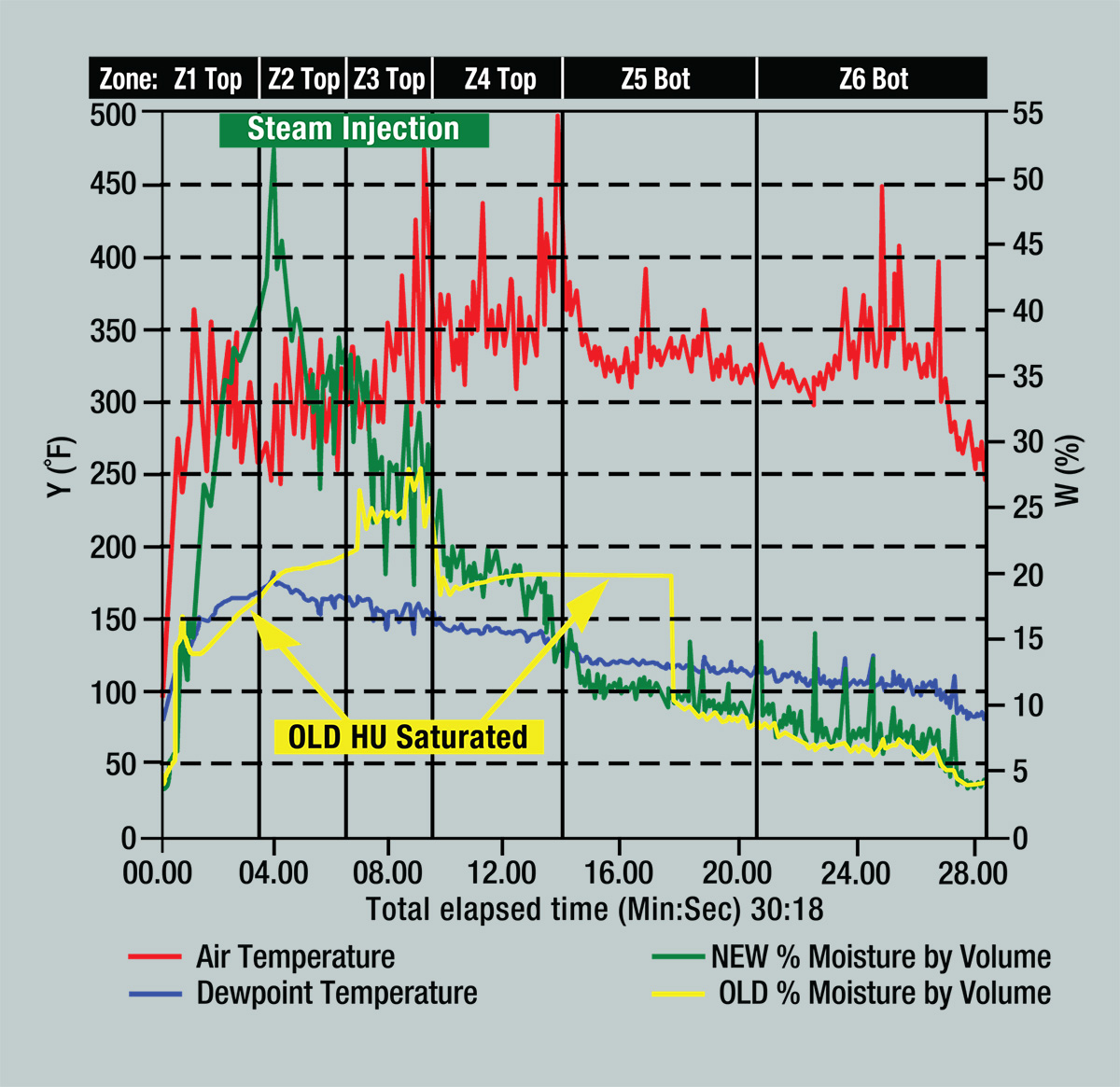

Anti-Saturation Technology™ allows measurements in high temperature and high dew point processes seen in commercial biscuit & cracker and bread & bun ovens.

Printable Version

Dr. Lin, founder of BakerPedia.com, discusses the critical nature of understanding and controlling steam in your Bread and Bun processes. Dr. Lin points out how doing an oven profile using the Reading Thermal Digital Humidity Sensor can help you obtain the desired product quality and throughput and identify factors keeping you from it.

SPECIAL OFFER

We are offering a 20% Discount on the NEW Digital Humidity Sensor to customers who trade in their OLD Analog Humidity Sensor before the end of June 2023. Click Here to contact us about your upgrade.